high temperature creep resistant materials|high temperature creep process : Big box store Heat treatment will directly change the microstructure of the material, which will affect the creep property of the titanium alloys . Balasundar et al. systematically . See more WEB4 de abr. de 2023 · Copa Libertadores. Ainda sem ter definido seu novo técnico, o Boca Juniors, da Argentina, faz nesta quinta-feira, 6 de abril, sua estreia na Copa Libertadores da América. Encara o Monagas, da Venezuela, em confronto que faz parte da agenda da primeira rodada da fase de grupos da edição 2023 do mais importante torneio de clubes .

{plog:ftitle_list}

Oxyprim in Tamil - ன் பயன்பாடுகள், மருந்தளவு, பக்க விளைவுகள், நன்மைகள் .

Processing conditions significantly affect the microstructure and properties of titanium alloys. Tian et al. studied the effect of α + β forging, near-β forging and β forging on microstructure and mechanical properties of TC17 titanium alloy. After the same heat treatment conditions, α + β forged alloy exhibits equiaxed . See more

Heat treatment will directly change the microstructure of the material, which will affect the creep property of the titanium alloys . Balasundar et al. systematically . See more

One of the major factors limiting the life of titanium alloys in service is their degradation due to gaseous environments. When titanium alloys are heated to . See more

A single-crystal alloy has excellent mechanical properties and high-temperature creep resistance, and it is the key material for manufacturing the core components of high . Abstract. There have been numerous efforts to develop creep-resistant materials strengthened by incoherent particles at high temperatures . Structural materials. Heat-resistant aluminium alloys . unprecedented high strength and creep resistance at 400 °C, which is approximately 80% of its absolute melting point. . circumstance to . 1. Introduction. Residual/ remnant life prediction, as a major element of prognosis and health management (PHM) of components and equipment subjected to high temperatures and stresses in industry, has been a major concern of researchers in recent years [1].At present, predicting the creep life of present and new generation creep-resistant materials which are .

A family of creep-resistant, alumina-forming austenitic (AFA) stainless steel alloys is under development for structural use in fossil energy conversion and combustion system applications. The AFA alloys developed to . Because creep resistance is lowered by exposure to high temperatures, workplaces must consider whether a material that is safe to use in one setting might become unsafe to use if transported into a higher-temperature setting. Creep occurs to materials that are placed under strain. Most materials that are or were used in building structures are .

Creep resistance is one of the most important mechanical properties for elevated-temperature structural applications, such as components for steam turbines in thermal-power plants 1,2,3,4,5,6 .The alloy exhibits a higher creep resistance and strength at high temperatures, making service temperatures of above 1060 °C possible for the material. The high resistivity of Mo-30W, an alloy of 70% molybdenum and 30% tungsten, against the attack of molten zinc makes it the ideal material for casting zinc. It is also used to construct valves .About DuPont™ Vespel® Polyimide. DuPont™ Vespel® Polyimide is an extremely high temperature, creep resistant plastic material that is often used in high heat environments where thermoplastic materials lose their mechanical properties. Vespel®, a lightweight alternative to metal, is available in a variety of formulations including unfilled grades and several low .

In addition to swelling resistance, ODS steels offer excellent high-temperature creep resistance. In ODS, the presence of nano-dispersoids (e.g. Y 2 O 3) or nano-clusters (e.g. Y–Ti–O) hinders the dislocation motion in the ferritic steel matrix. Furthermore, the nano-clusters or nano-dispersoids act as a sink of defects induced by radiation. In this study, the creep deformation behavior of conditioning-treated Co-Cr-W-Ni-based cast superalloy with and without B and Zr additions was investigated using constant load creep tests conducted at temperatures of 700 °C (973 K) and 800 °C (1073 K) and stresses ranging from 200 to 400 MPa. For both alloys, secondary creep strains were analyzed in . The tensile yield strength versus temperature plot of HESA comparing to those of the commercial Ni-based superalloys 29,30,31 and reported high entropy alloys 10,32,33,34 are shown in Fig. 4.The . An interface modification strategy has been developed to uniformly distribute high-density sub-10 nm coherent MgO particles in an Al matrix, resulting in high strength and creep resistance at .

suga salt spray chamber

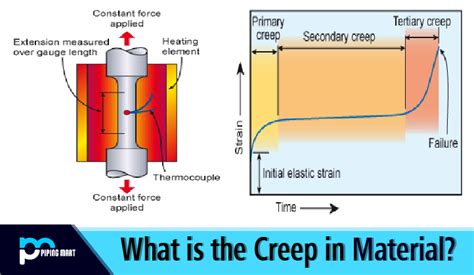

Creep is a major concern, since it can cause materials to progressively deform, and possibly to fail, under applied stresses below their yield stress. . Be familiar with a particular set-up for experimental study of the creep characteristics of a material, available in wire form < li=""> /li> . 12.7: Designing for Creep Resistance - Nickel . Nickel-based single-crystal superalloys are mainly composed of a disordered γ-Ni matrix (Ni, FCC structure) and an ordered γ-Ni 3 Al strengthening phase (Ni 3 Al, FCC structure). A single-crystal alloy has excellent mechanical properties and high-temperature creep resistance, and it is the key material for manufacturing the core components of high-power .

Creep-resistant materials are used in machines and facilities operated at high temperatures e.g. power engineering equipment. They must be able to withstand the highest possible operating loads at elevated temperatures and also be sufficiently resistant to high-temperature corrosion.

The use of molten-salt–based energy production and storage systems requires high-temperature corrosion- and creep-resistant structural materials. This study investigated the microstructure .

steel salt spray chamber

The high-temperature resistance of these materials makes them ideal for use under extreme conditions. Similarly, creep-resistant polymers find extensive application in the aerospace industry where they are utilized to manufacture . A nanocrystalline copper–tantalum alloy with high strength and extremely high-temperature creep resistance is achieved via a processing method that creates clusters of atoms within the alloy . When materials are required to withstand long-term stress at high temperatures, then creep-resistant super alloys are preferred as they are highly creep resistant. Creep Failure Creep failure is a time-dependent plastic deformation of a material that has been exposed to constant stress, with higher temperatures increasing the likelihood of . The degree of crystallinity and the presence of additives or fillers impact creep resistance. Techniques like cross-linking or blending with other materials enhance polymer creep performance. Ceramics. Ceramics are known for high-temperature stability and creep resistance, suitable for harsh environments like furnaces and kilns.

This paper presents a non-contact method for creep measurements of ultra-high-temperature materials at 2300 °C. Using the electrostatic levitation facility at NASA MSFC, a spherical sample was rotated quickly enough to cause creep . Creep properties of the experimental superalloy were investigated in the temperature range 1073–1223 K and stress range 110–550 MPa. The observations of dislocation structures during different creep conditions reveal that in the high stress region, particle-shearing mechanisms including stacking fault formation and antiphase boundary creation are operative .Creep Resistance: The ability of a material to resist deformation under mechanical stress at high temperatures. . High-temperature materials are indispensable in the field of Material Science in Engineering, enabling the development and operation of advanced technologies across various industries. From their fundamental principles and . High-temperature creep resistant ternary blends based on polyethylene and polypropylene for thermoplastic power cable insulation. Yingwei Ouyang, . (Figure 1 and Figure S1) and by the surroundings. 3 To prevent any gradual deformation, a material with excellent creep resistance at elevated temperatures is required. .

high temperature creep resistance

Adding homogeneously dispersed oxide nanoparticles to aluminium pushes its high-temperature strength up to 500 °C. . These materials possess very good creep resistance up to 650 °C and do not . J. Mater. Sci. Technol., 2011, 27(4), 344-351. Microstructure Evolution of a 10Cr Heat-Resistant Steel during High Temperature Creep Ping Hu 1,2) ,WeiYan 1)†, Wei Sha 3) ,WeiWang 4) , Yiyin Shan 1) and Ke Yang 1) 1) Institute of Metal Research, Chinese Academy of Sciences, Shenyang 110016, China 2) Graduate School of Chinese Academy of Sciences, .

1253.12 Creep-resistant Al-base Materials: Composites _____ 23 . when a material is exposed to high temperature under a constant applied stress (or load). Creep is observed in all metals, provided that the operating temperature (T) exceeds 0.3-0.5 TM, where TM is the absolute melting temperature. The following The material strength at high temperature becomes a major issue and the steel resistance to creep under severe conditions (temperature, stress) limits the maximum application temperature [9]. For superheater tube production, steels with a .

high temperature creep process

salt spray chamber test

May 7, 2015. 44min. 16+. Em uma viagem de negócios, o governador do Acre, Edmundo Pinto, se hospeda no mesmo hotel onde sempre se instalava em São Paulo-SP. Com medo de estar sendo perseguido, o político se surpreende com um assalto e entra em confronto com o criminoso, sendo alvejado por um disparo revólver.

high temperature creep resistant materials|high temperature creep process